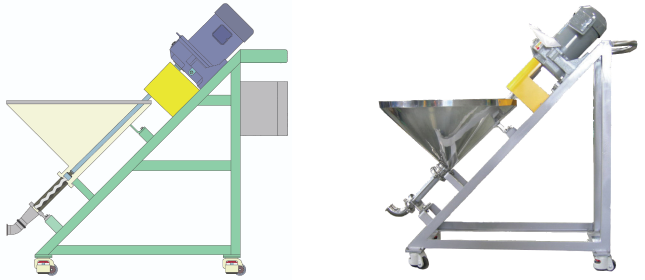

KH/KHF Hopper integrated Pump with hopper type casing

KH General Use, KHF Sanitary

Hopper and pump are integrated. The liquid is temporarily stored in the hopper and dispensed as needed. Since it is easy to disassemble and clean, it is optimal for food or liquids that easily solidify

Features

- KH Type has no shaft seal, so it is easy for operation and maintenance

- Space-saving type, that hopper and pump casing are integrated

- The structure is simple and open so the inside is easily cleaned

- It is proper for transferring various types of resin binders and organic solvent-based paints

Applications

- Various mortars such as glass fiber mortar and resin mortar, high-viscosity paint, sealing agent, caulking agent, adhesive, bulgogi seasoning, fish roe, dressing, paint ink, fish cake dough, etc

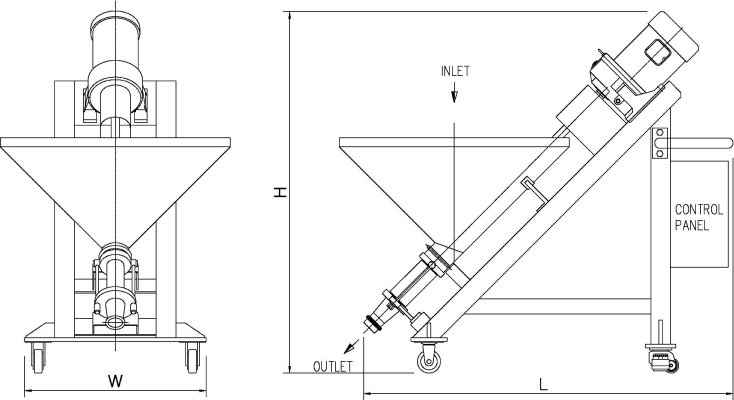

- Performance and dimensions

- Filling valve combination KHF+FV

Performance and dimensions

Performance and dimensions of KH type

| Model | Connection (Ferrule) |

Discharge Pressure (max.kgf/cm²) |

Flow rate ℓ/min |

Power (kW) |

Standard Hopper (ℓ) |

Dimensions (appr.) |

Wt (Kg) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 60Hz | |||||||||||

| L | H | W | |||||||||

| 175rpm | 350rpm | ||||||||||

| KH15 | 1 1/2S | 4.5 | 2.5 | 5 | 0.4 | 60 | 800 | 1100 | 380 | 50 | |

| 2KH15 | 1 1/2S | 9 | 2.5 | 5 | 0.4 | 60 | 850 | 1100 | 380 | 55 | |

| KH20 | 1 1/2S | 6 | 5 | 10 | 0.4 | 60 | 850 | 1100 | 500 | 65 | |

| 2KH20 | 1 1/2S | 12 | 5 | 10 | 0.75 | 60 | 900 | 1100 | 500 | 80 | |

| KH30 | 2S | 6 | 16 | 32 | 0.75 | 80 | 1250 | 1200 | 600 | 90 | |

| 2KH30 | 2S | 12 | 16 | 32 | 1.5 | 80 | 1300 | 1200 | 600 | 110 | |

| KH40 | 2 1/2S | 6 | 40 | 80 | 1.5 | 100 | 1350 | 1300 | 700 | 130 | |

| 2KH40 | 2 1/2S | 12 | 40 | 80 | 2.2 | 3.7 | 100 | 1450 | 1350 | 700 | 150 |

| KH50 | 3S | 6 | 80 | 160 | 2.2 | 2.2 | 150 | 1600 | 1600 | 850 | 165 |

| 2KH50 | 3S | 12 | 80 | 160 | 3.7 | 5.5 | 150 | 1800 | 1700 | 900 | 180 |

- Appropriate rotation speed is selected in consideration of liquid viscosity, abrasiveness, etc

- If the discharge flow rate needs to be adjusted, use an inverter to control from 20% to 130% of the motor speed

Example of using KHF and filling valve combination type KHF+FV

KHF+FV type specifications

| Model | Min, filling flow rate (㎖/time) |

Filling flow rate (㎖/s) |

Filling precision (㎖) |

Min, filling capacity (time/min) |

Capacity (ℓ) |

Power (KW) |

|---|---|---|---|---|---|---|

| 2KHF15+FV | 25 | 15~100 | ±1 | 15 | 60 | 0.4 |

| 2KHF20+FV | 60 | 30~200 | ±2 | 15 | 60 | 0.75 |

| KHF30+FV | 200 | 130~800 | ±5 | 15 | 100 | 1.5 |

| KHF40+FV | 500 | 280~1700 | ±15 | 15 | 150 | 2.2 |

- By combining KHF with the Filling valve, the liquid in the hopper can be precisely injected to the desired volume for metered filling