Features and Advantages of MONAS

- Any liquids

- No capacity restrictions

- Excellent performance

- Efficient system planning

Can transfer Any liquids

1 High-concentration and high-viscosity liquids

- From water, to viscous liquids are smoothly transferred.

- Organic and inorganic sludges, Coating colour, Food, etc.

2 Ultra-high viscosity liquids

- It also transfer non-fluid, ultra-high-viscosity materials such as dehydrated sludge cake or grease, dough from food factories.

3 Liquids containing suspended solids and fibers

- Liquids containing a large volume of suspended solids and fibers are also transferable

4 Liquids containing gases and air bubbles

- Liquids that generate gas or containing air bubbles such as floating separation sludge, and pressurized water are transferred and injected without causing vapor lock.

5 Various chemicals

- Various chemical solutions used in chemical and water treatment processes are precisely controlled and injected.

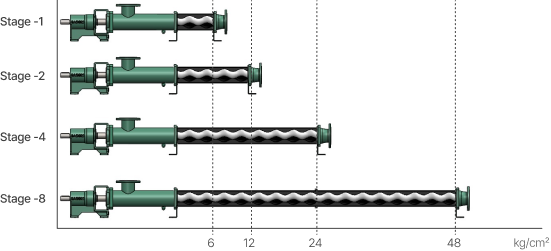

With various models No capacity restrictions

1 High discharge pressure

- The discharge volume keeps constant even when the discharge pressure changes.

- High discharge pressure with small capacity is possible

- High-pressure enables long-distance transport of dehydrated cake and supply to permeable membrane

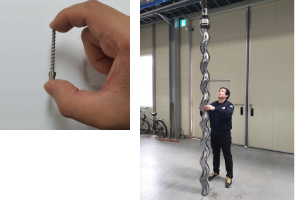

2 From very small to large capacity

- The discharge capacity ranges from a minimum of 0.1 cc/min to a maximum of 500 m³/hr

- Rotor diameter is Ø2~ Ø150

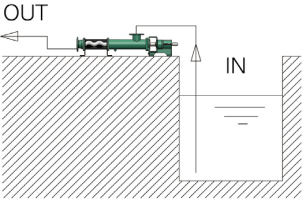

3 Strong suction

- With strong suction, high vacuum of 8.5m or more is possible

- The suction lift of 4-5m is possible even with highly concentrated sludge of 4-5%

- If necessary, a vacuum level of more than 9m is possible

4 Various wet end materials

- The material of the wet end parts can be freely selected to meet the liquid to be transferred. Acid, alkali, oil, solvent, abrasion resistance, etc.

Free control and smooth flow

Excellent performance Excellent performance

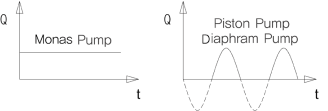

1 Quiet, pulsation-free metered transfer

- Progressive cavity pumps provide pulsation-free, quiet and metered transfer due to the unique principle of uniform transfer flow

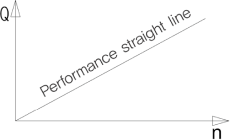

2 Discharge quantity is proportional to rotation

- You can freely control the discharge quantity by adjusting the rotation speed

- Precise metered discharge regardless of sludge concentration or suction fluctuations

3 No damage to fluids

- The product of cosmetic or food ingredients is not damaged during trasfer

- In the dewatering process of sludge, it does not damage the coagulated floc

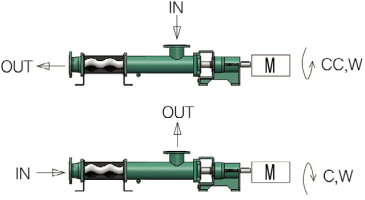

4 Suction and discharge reversible

- By reversing the rotation of the motor, the direction of liquid flow is easily changed

To meet the process requirement

Efficient system planning Efficient system planning

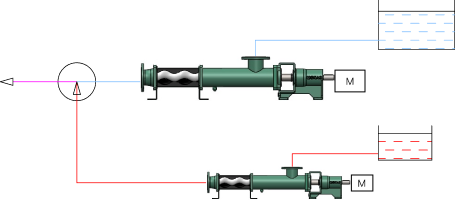

1 Precise proportional injection

- Two or more liquids can be mixed in a constant ratio

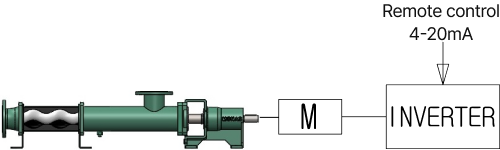

2 Free remote control and automation

- By controlling the number of revolutions, the pump capacity can be remotely controlled and operated automatically

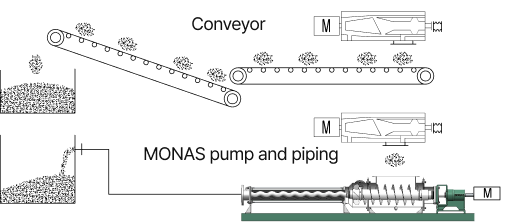

3 Dehydrated cake is conveyed thru pipe

- Dehydrated cakes are transfered over long distances through pipe rather than a conveyor with no odor

4 Easy and free installation

- Facility planning is easy and free to meet site conditions with variety of pump types

5 Various applications are possible

- Various application facilities such as filling machines can be customized