KA Basic Type Pump Basic model that can handle a variety of transfer liquids

We have abundant models with various materials. It is possible to assemble various drive reducers and has a wide range of applications. It is widely used for applications requiring nonpulsation, constant discharge, automatic control and systemization of various liquid transfer lines.

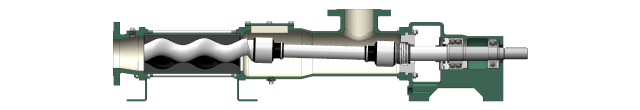

Bearing Block Type KA-B

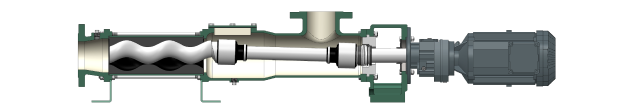

Mono Block Type KA-M

Features

- Water-like liquid as well as high viscosity medium

- Liquids containing a large volume of suspended solids and fibers are also transferred

- Pulsation-free and accurate feeding

- The flow control range is wide and free

- Optimal for automatic control because it responds quickly to control signals

- Strong self-priming ability (suction lift 8.5m)

- High discharge pressure

- Silent flow without pulsation, vortex and interruption.

- Simple structure enable easy maintenance

Applications

- Chemicals, paints, cosmetics, paper & pulp, sugar, food industry, ceramics, agriculture and fisheries, civil construction, mining, ships, water treatment, concentrated sludge, chemical liquid sludge, coagulant, oil sludge, and bilge

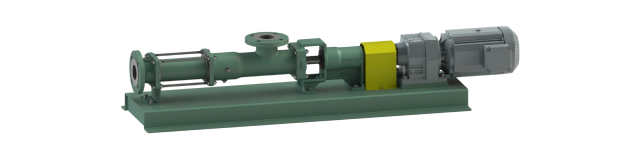

Monoblock KA-M in-line Type

Compact monoblock type with direct coupled between driver and pump

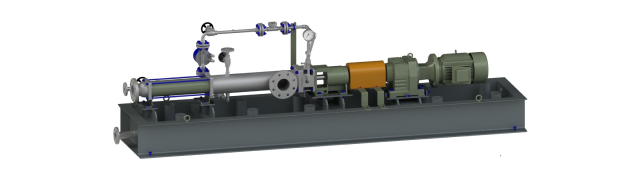

Bearingblock KA-B in-line Type

Bearing block type that can be used with various reduction motors

Bearingblock KA-B Overhead mounting

V-Belt overhead mounted bearing block type

- For small pumps for chemical injection, please refer to the KL type.

KAP - API pump for petrochemical

MONAS KA pumps for petrochemical plants can be manufactured according to the requirements of API 676.

- Performance and dimensions Bare Shaft

- Performance and dimensions Direct Coupled in-line

- Performance and dimensions V-Belt Drive

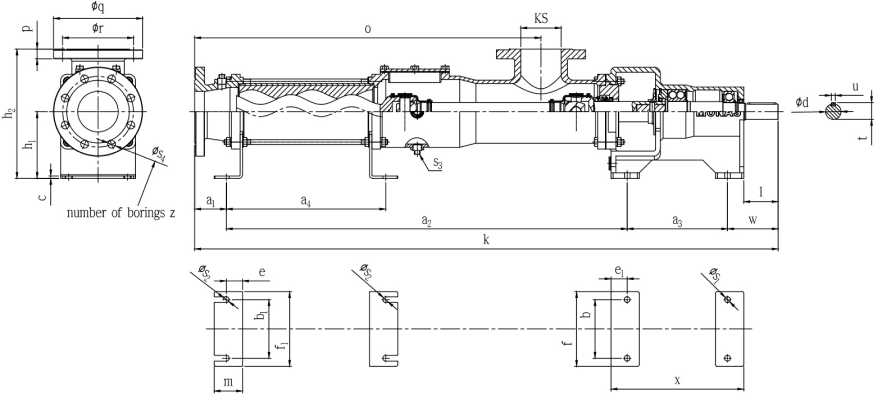

1Standard dimensions

Standard dimensions for KA-B(Bearing Block) type proper with bare shaft(Basic type)

| Model | Standard dimensions | Suction/Discharge | Shaft End | Wt | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a1 | a2 | a3 | a4 | b | b1 | c | e | e1 | f | f1 | h1 | h2 | k | m | o | s1 | s2 | s3 | x | KS | p | q | r | s4 | z | d | l | t | u | w | kg | |

| KA15 | 43 | 335 | 162 | - | 75 | 75 | 5 | 25 | 25 | 95 | 95 | 100 | 185 | 609 | 40 | 273 | 9 | 9 | PT 1/4 | 212 | 20A | 18 | 105 | 75 | 15 | 4 | 16 | 44 | 18 | 5 | 59 | 16 |

| 2KA15 | 43 | 415 | 162 | - | 75 | 75 | 5 | 25 | 25 | 95 | 95 | 100 | 185 | 689 | 40 | 353 | 9 | 9 | PT 1/4 | 212 | 20A | 18 | 105 | 75 | 15 | 4 | 16 | 44 | 18 | 5 | 59 | 16 |

| KA20 | 53 | 382 | 162 | - | 75 | 75 | 5 | 25 | 25 | 95 | 95 | 100 | 190 | 666 | 40 | 315 | 9 | 9 | PT 1/4 | 212 | 32A | 20 | 140 | 100 | 19 | 4 | 16 | 44 | 18 | 5 | 59 | 19 |

| 2KA20 / KA22 |

53 | 482 | 162 | - | 75 | 75 | 5 | 25 | 25 | 95 | 95 | 100 | 190 | 766 | 40 | 415 | 9 | 9 | PT 1/4 | 212 | 32A | 20 | 140 | 100 | 19 | 4 | 16 | 44 | 18 | 5 | 59 | 20 |

| KA30 | 58 | 541 | 193 | - | 85 | 85 | 5 | 30 | 30 | 115 | 115 | 115 | 220 | 876 | 50 | 448 | 11 | 11 | PT 3/8 | 253 | 50A | 20 | 165 | 120 | 19 | 4 | 22 | 54 | 24.5 | 6 | 84 | 33 |

| 2KA30 / KA32 |

58 | 691 | 193 | 367 | 85 | 85 | 5 | 30 | 30 | 115 | 115 | 115 | 220 | 1026 | 50 | 598 | 11 | 11 | PT 3/8 | 253 | 50A | 20 | 165 | 120 | 19 | 4 | 22 | 54 | 24.5 | 6 | 84 | 34 |

| KA40 | 63 | 695 | 199 | - | 105 | 105 | 6 | 35 | 35 | 135 | 135 | 130 | 245 | 1056 | 55 | 580 | 11 | 11 | PT 3/8 | 269 | 65A | 22 | 185 | 140 | 19 | 4 | 25 | 64 | 28 | 8 | 99 | 52 |

| 2KA40 / KA42 |

63 | 895 | 199 | 478 | 105 | 105 | 6 | 35 | 35 | 135 | 135 | 130 | 245 | 1256 | 55 | 780 | 11 | 11 | PT 3/8 | 269 | 65A | 22 | 185 | 140 | 19 | 4 | 25 | 64 | 28 | 8 | 99 | 58 |

| KA50 | 73 | 828 | 225 | - | 127 | 127 | 6 | 35 | 35 | 160 | 160 | 155 | 290 | 1245 | 60 | 715 | 14 | 14 | PT 1/2 | 295 | 80A | 24 | 200 | 150 | 19 | 8 | 32 | 84 | 35 | 10 | 119 | 76 |

| 2KA50 / KA52 |

73 | 1068 | 225 | 563 | 127 | 127 | 6 | 35 | 35 | 160 | 160 | 155 | 290 | 1485 | 60 | 955 | 14 | 14 | PT 1/2 | 295 | 80A | 24 | 200 | 150 | 19 | 8 | 32 | 84 | 35 | 10 | 119 | 83 |

| KA60 | 78 | 991 | 248 | 394 | 145 | 145 | 6 | 40 | 40 | 185 | 185 | 165 | 320 | 1442 | 70 | 856 | 14 | 14 | PT 1/2 | 328 | 100A | 24 | 220 | 175 | 19 | 8 | 38 | 85 | 41 | 10 | 125 | 114 |

| 2KA60 / KA62 |

78 | 1291 | 248 | 694 | 145 | 145 | 6 | 40 | 40 | 185 | 185 | 165 | 320 | 1742 | 70 | 1156 | 14 | 14 | PT 1/2 | 328 | 100A | 24 | 220 | 175 | 19 | 8 | 38 | 85 | 41 | 10 | 125 | 122 |

| KA80 | 83 | 1247 | 278 | 514 | 185 | 185 | 8 | 45 | 45 | 235 | 235 | 200 | 380 | 1769 | 80 | 1083 | 18 | 18 | PT 3/4 | 368 | 125A | 24 | 250 | 210 | 23 | 8 | 48 | 116 | 51.5 | 14 | 161 | 200 |

| 2KA80 / KA82 |

83 | 1647 | 278 | 914 | 185 | 185 | 8 | 45 | 45 | 235 | 235 | 200 | 380 | 2169 | 80 | 1483 | 18 | 18 | PT 3/4 | 368 | 125A | 24 | 250 | 210 | 23 | 8 | 48 | 116 | 51.5 | 14 | 161 | 216 |

| KA100 | 98 | 1500 | 328 | 630 | 215 | 215 | 8 | 50 | 50 | 285 | 285 | 230 | 440 | 2123 | 90 | 1318 | 22 | 22 | PT 3/4 | 428 | 150A | 26 | 285 | 240 | 23 | 8 | 60 | 147 | 64 | 18 | 197 | 334 |

| 2KA100 / KA102 |

98 | 2000 | 328 | 1130 | 215 | 215 | 8 | 50 | 50 | 285 | 285 | 230 | 440 | 2623 | 90 | 1818 | 22 | 22 | PT 3/4 | 428 | 150A | 26 | 285 | 240 | 23 | 8 | 60 | 147 | 64 | 18 | 197 | 366 |

| KA120 | 98 | 1731 | 366 | 770 | 260 | 260 | 8 | 70 | 70 | 340 | 340 | 275 | 520 | 2413 | 120 | 1500 | 26 | 26 | PT 1 | 506 | 200A | 28 | 343 | 290 | 23 | 12 | 75 | 148 | 79.5 | 20 | 218 | 563 |

| 2KA120 / KA122 |

98 | 2331 | 366 | 1370 | 260 | 260 | 8 | 70 | 70 | 340 | 340 | 275 | 520 | 3013 | 120 | 2100 | 26 | 26 | PT 1 | 506 | 200A | 28 | 343 | 290 | 23 | 12 | 75 | 148 | 79.5 | 20 | 218 | 616 |

| KA150 | 182 | 2243 | 366 | 927 | 260 | 280 | 10 | 70 | 70 | 340 | 360 | 275 | 550 | 3009 | 120 | 1996 | 26 | 26 | PT1 | 506 | 250A | 24 | 400 | 355 | 25 | 12 | 75 | 148 | 79.5 | 20 | 218 | 595 |

| 2KA150 / KA152 |

182 | 2243 | 366 | 1677 | 260 | 280 | 10 | 70 | 70 | 340 | 360 | 275 | 550 | 3759 | 120 | 2746 | 26 | 26 | PT1 | 506 | 250A | 24 | 400 | 355 | 25 | 12 | 75 | 148 | 79.5 | 20 | 218 | 677 |

2 Performance table

KA type 1-stage pump performance table - Based on discharge pressure of 4kg/cm²

| Model | Connection (A) |

Flow rate (m³/hr) |

Rotation (rpm) |

(Hz) | (kW) | ||

|---|---|---|---|---|---|---|---|

| min | max | min | max | ||||

| 2KA15 | 20 | 0.07 | 0.35 | 210 | 710 | 20~70 | 0.4 |

| KA20 | 32 | 0.07 | 0.71 | 200 | 650 | 20~70 | 0.75 |

| KA30 | 50 | 0.75 | 3 | 255 | 630 | 20~70 | 1.5 |

| KA40 | 65 | 1.8 | 6 | 255 | 540 | 20~70 | 2.2 |

| KA50 | 80 | 3.6 | 11 | 220 | 530 | 20~70 | 3.7 |

| KA60 | 100 | 6 | 19 | 180 | 450 | 20~70 | 5.5 |

| KA69 | 100 | 5.6 | 28 | 120 | 400 | 20~70 | 5.5 |

| KA80 | 125 | 7 | 40 | 100 | 400 | 20~70 | 7.5 |

| KA89 | 125 | 8.5 | 50 | 100 | 400 | 20~70 | 11 |

| KA100 | 150 | 17 | 68 | 120 | 350 | 20~60 | 18.5 |

| KA120 | 200 | 29 | 120 | 110 | 350 | 20~60 | 22 |

| KA150 | 250 | 50 | 240 | 90 | 350 | 20~60 | 45 |

KKA type 2-stage pump performance table - Based on discharge pressure of 8kg/cm³

| Model | Connection (A) |

Flow rate (m³/hr) |

Rotation (rpm) |

(Hz) | (kW) | ||

|---|---|---|---|---|---|---|---|

| min | max | min | max | ||||

| 4KA15 | 20 | 0.1 | 0.47 | 175 | 640 | 20~70 | 0.75 |

| 2KA20 | 32 | 0.2 | 0.8 | 275 | 615 | 20~70 | 0.75 |

| 2KA30 | 50 | 0.7 | 3 | 230 | 615 | 20~70 | 2.2 |

| 2KA40 | 65 | 1.5 | 6 | 205 | 520 | 20~70 | 3.7 |

| 2KA50 | 80 | 2.7 | 11 | 200 | 515 | 20~70 | 5.5 |

| 2KA60 | 100 | 4.4 | 17.9 | 155 | 440 | 20~70 | 11 |

| 2KA80 | 125 | 8.7 | 35.8 | 135 | 370 | 20~70 | 15 |

| 2KA100 | 150 | 13.5 | 54 | 110 | 290 | 20~60 | 30 |

| 2KA120 | 200 | 19.4 | 80 | 100 | 260 | 20~60 | 37 |

| 2KA150 | 250 | 45 | 155 | 90 | 230 | 20~60 | 75 |

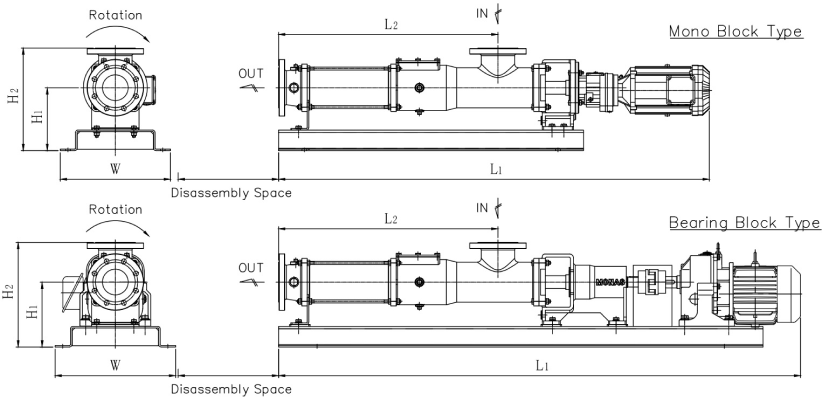

Performance and dimensions

Example of KA type application for sludge and polymer - Discharge pressure 2kg/cm², Direct coupled in-line type

- Geared motor deceleration Direct coupled In-line type

- Inverter speed change type

- GC200 casing

Performance and dimensions of sludge transfer pumps

| Model | Connection (A) |

Dischare pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) |

Power (kW) |

Dimensions (appr.) |

Disassembly Space |

Wt (Kg) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mono Block Type | Bearing Block Type | |||||||||||||||||||

| min | max | min | max | L1 | L2 | H1 | H2 | W1 | L1 | L2 | H1 | H2 | W | |||||||

| KA15 | 20 | 2 | 0.23 | 0.45 | 5.0~2.7 | 345 | 640 | 0.4 | 757 | 273 | 180 | 265 | 225 | 957 | 273 | 185 | 270 | 305 | 100 | 34 / 51 |

| KA20 | 32 | 2 | 0.55 | 1.02 | 5.0~2.7 | 345 | 640 | 0.75 | 916 | 315 | 180 | 270 | 225 | 1091 | 315 | 215 | 305 | 340 | 125 | 44 / 76 |

| KA30 | 50 | 2 | 2.02 | 3.34 | 5.0~3.0 | 350 | 580 | 1.5 | 1151 | 448 | 195 | 300 | 265 | 1410 | 448 | 233 | 338 | 400 | 190 | 68 / 123 |

| KA40 | 65 | 2 | 4.84 | 7.26 | 5.0~3.3 | 350 | 525 | 2.2 | 1354 | 580 | 210 | 325 | 285 | 1708 | 580 | 252 | 367 | 440 | 250 | 96 / 174 |

| KA50 | 80 | 2 | 8.96 | 12.80 | 5.0~3.5 | 350 | 500 | 3.7 | 1517 | 715 | 235 | 370 | 320 | 1876 | 715 | 252 | 387 | 440 | 300 | 137 / 214 |

| KA60 | 100 | 2 | 13.38 | 22.16 | 6.0~3.7 | 290 | 475 | 5.5 | 1787 | 856 | 245 | 400 | 345 | 2144 | 856 | 261 | 416 | 470 | 370 | 207 / 303 |

| KA69 | 100 | 2 | 22.55 | 36.94 | 6.0~3.7 | 290 | 475 | 5.5 | 2005 | 1074 | 245 | 400 | 345 | 2362 | 1074 | 261 | 416 | 470 | 590 | 218 / 314 |

| KA80 | 125 | 2 | 32.43 | 53.11 | 6.0~3.7 | 290 | 475 | 7.5 | 2078 | 1083 | 290 | 470 | 420 | 2571 | 1083 | 350 | 530 | 480 | 490 | 321 / 497 |

| KA89 | 125 | 2 | 40.54 | 55.91 | 6.0~4.4 | 290 | 400 | 11 | 2198 | 1193 | 290 | 470 | 420 | 2694 | 1193 | 355 | 535 | 530 | 600 | 393 / 607 |

| KA100 | 150 | 2 | 64.03 | 88.32 | 6.0~4.4 | 290 | 400 | 15 | 2520 | 1318 | 330 | 540 | 540 | 3116 | 1318 | 405 | 615 | 560 | 610 | 600 / 820 |

| KA120 | 200 | 2 | 94.35 | 132.09 | 7.0~5.0 | 250 | 350 | 18.5 | 2782 | 1500 | 375 | 620 | 540 | 3415 | 1500 | 425 | 670 | 570 | 730 | 823 / 974 |

| KA150 | 250 | 2 | 86.46 | 184.28 | 15.0~7.0 | 117 | 250 | 30 | - | - | - | - | - | 4165 | 1996 | 425 | 700 | 590 | 920 | - / 1221 |

| KA22 | 32 | 2 | 1.10 | 2.04 | 5.0~2.7 | 345 | 640 | 0.75 | 1016 | 415 | 180 | 270 | 225 | 1191 | 415 | 215 | 305 | 340 | 225 | 46 / 79 |

| KA32 | 50 | 2 | 4.04 | 6.68 | 5.0~3.0 | 350 | 580 | 1.5 | 1301 | 598 | 195 | 300 | 265 | 1560 | 598 | 233 | 338 | 400 | 340 | 73 / 130 |

| KA42 | 65 | 2 | 9.68 | 14.52 | 5.0~3.3 | 350 | 525 | 3.7 | 1563 | 780 | 210 | 325 | 285 | 1887 | 780 | 252 | 367 | 440 | 450 | 117 / 199 |

| KA52 | 80 | 2 | 17.92 | 25.60 | 5.0~3.5 | 350 | 500 | 5.5 | 1863 | 955 | 235 | 370 | 320 | 2187 | 955 | 277 | 412 | 500 | 540 | 189 / 294 |

| KA62 | 100 | 2 | 26.76 | 44.32 | 6.0~3.7 | 290 | 475 | 7.5 | 2105 | 1156 | 245 | 400 | 345 | 2482 | 1156 | 261 | 416 | 470 | 670 | 232 / 341 |

| KA82 | 125 | 2 | 64.86 | 106.22 | 6.0~3.7 | 290 | 475 | 11 | 2591 | 1483 | 290 | 470 | 420 | 3085 | 1483 | 355 | 535 | 530 | 590 | 412 / 626 |

| KA102 | 150 | 2 | 88.00 | 132.00 | 8.7~5.8 | 200 | 300 | 15 | 3020 | 1818 | 330 | 540 | 540 | 3619 | 1818 | 405 | 615 | 560 | 1110 | 688 / 851 |

Performance and dimensions of polymer transfer pumps

| Model | Connection (A) |

Dischare pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) |

Power (kW) |

Dimensions (appr.) |

Disassembly Space |

Wt (Kg) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mono Block Type | Bearing Block Type | |||||||||||||||||||

| min | max | min | max | L1 | L2 | H1 | H2 | W1 | L1 | L2 | H1 | H2 | W | |||||||

| KA15 | 20 | 2 | 0.23 | 0.67 | 5.0~1.8 | 345 | 960 | 0.4 | 757 | 273 | 180 | 265 | 225 | 957 | 273 | 185 | 270 | 305 | 100 | 34 / 51 |

| KA20 | 32 | 2 | 0.55 | 1.38 | 5.0~2.0 | 345 | 865 | 0.75 | 916 | 315 | 180 | 270 | 225 | 1091 | 315 | 215 | 305 | 340 | 125 | 44 / 76 |

| KA30 | 50 | 2 | 2.02 | 5.02 | 5.0~2.0 | 350 | 870 | 1.5 | 1151 | 448 | 195 | 300 | 265 | 1410 | 448 | 233 | 338 | 400 | 190 | 68 / 123 |

| KA40 | 65 | 2 | 4.84 | 9.61 | 5.0~2.5 | 350 | 695 | 2.2 | 1354 | 580 | 210 | 325 | 285 | 1708 | 580 | 252 | 367 | 440 | 250 | 96 / 174 |

| KA50 | 80 | 2 | 8.96 | 14.85 | 5.0~3.0 | 350 | 580 | 3.7 | 1517 | 715 | 235 | 370 | 320 | 1876 | 715 | 252 | 387 | 440 | 300 | 137 / 214 |

| KA60 | 100 | 2 | 13.38 | 22.16 | 6.0~3.7 | 290 | 475 | 5.5 | 1787 | 856 | 245 | 400 | 345 | 2144 | 856 | 261 | 416 | 470 | 370 | 207 / 303 |

| KA22 | 32 | 2 | 1.10 | 2.76 | 5.0~2.0 | 345 | 865 | 0.75 | 1016 | 415 | 180 | 270 | 225 | 1191 | 415 | 215 | 305 | 340 | 225 | 46 / 79 |

| KA32 | 50 | 2 | 4.04 | 10.04 | 5.0~2.0 | 350 | 870 | 1.5 | 1301 | 598 | 195 | 300 | 265 | 1560 | 598 | 233 | 338 | 400 | 340 | 73 / 130 |

| KA42 | 65 | 2 | 9.68 | 19.22 | 5.0~2.5 | 350 | 695 | 3.7 | 1563 | 780 | 210 | 325 | 285 | 1887 | 780 | 252 | 367 | 440 | 450 | 117 / 199 |

| KA52 | 80 | 2 | 17.92 | 29.7 | 5.0~3.0 | 350 | 580 | 5.5 | 1863 | 955 | 235 | 370 | 320 | 2187 | 955 | 277 | 412 | 500 | 540 | 189 / 294 |

| KA62 | 100 | 2 | 26.76 | 44.32 | 6.0~3.7 | 290 | 475 | 7.5 | 2105 | 1156 | 245 | 400 | 345 | 2482 | 1156 | 261 | 416 | 470 | 670 | 232 / 341 |

- The above are reference dimensions for equipment layout review.

- When adjusting motor rpm with inverter, use within the range of 20Hz to 60Hz.

- Use an inverter that is one step larger than the motor.

- The motor rpm is based on a 4-pole motor (1750RPM).

- Refer to page 20 for wetted part material and shaft seal specifications.

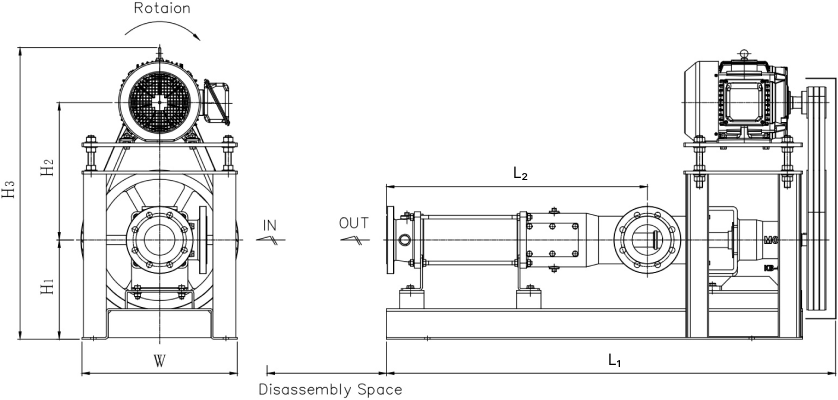

Performance and dimensions

Example of KA type application for sludge and polymer - Discharge pressure 2kg/cm², Overhead mounting/V-belt drive type

- V-belt speed deceleration Overhead mounting

- Inverter speed change type

Performance and dimensions of sludge transfer pumps

| Model | Connection (A) |

Dischare pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) | Power (kW) |

Dimensions (appr.) |

Disassembly Space | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | L1 | L2 | H1 | H2 | H3 | W | ||||||

| KA15 | 20 | 2 | 0.18 | 0.45 | 6.4~2.7 | 273 | 640 | 0.4 | 640 | 273 | 245 | 335 | 672 | 310 | 100 |

| KA20 | 32 | 2 | 0.52 | 1.02 | 5.3~2.7 | 328 | 640 | 0.75 | 700 | 315 | 245 | 335 | 672 | 330 | 125 |

| KA30 | 50 | 2 | 1.68 | 3.34 | 6.0~3.0 | 292 | 580 | 1.5 | 910 | 448 | 260 | 370 | 732 | 390 | 190 |

| KA40 | 65 | 2 | 4.23 | 7.26 | 5.7~3.3 | 306 | 525 | 2.2 | 1085 | 580 | 275 | 400 | 790 | 410 | 250 |

| KA50 | 80 | 2 | 7.12 | 12.80 | 6.3~3.5 | 278 | 500 | 3.7 | 1270 | 715 | 320 | 452 | 896 | 470 | 300 |

| KA60 | 100 | 2 | 15.13 | 22.16 | 5.3~3.7 | 328 | 475 | 5.5 | 1475 | 856 | 330 | 502 | 1013 | 500 | 370 |

| KA69 | 100 | 2 | 25.51 | 36.94 | 5.3~3.7 | 328 | 475 | 5.5 | 1693 | 1074 | 330 | 502 | 1013 | 500 | 590 |

| KA80 | 125 | 2 | 35.00 | 53.11 | 5.6~3.7 | 313 | 475 | 7.5 | 1800 | 1083 | 385 | 522 | 1088 | 530 | 490 |

| KA89 | 125 | 2 | 43.75 | 55.91 | 5.6~3.7 | 313 | 475 | 11 | 1920 | 1193 | 385 | 550 | 1149 | 530 | 600 |

| KA100 | 150 | 2 | 66.46 | 88.32 | 5.8~4.4 | 301 | 400 | 15 | 2160 | 1318 | 445 | 580 | 1239 | 780 | 610 |

| KA120 | 200 | 2 | 110.20 | 132.09 | 6.0~5.0 | 292 | 350 | 18.5 | 2445 | 1500 | 515 | 630 | 1368 | 845 | 730 |

| KA22 | 32 | 2 | 1.05 | 2.04 | 5.3~2.7 | 328 | 640 | 0.75 | 800 | 415 | 245 | 335 | 672 | 330 | 225 |

| KA32 | 50 | 2 | 3.37 | 6.68 | 6.0~3.0 | 292 | 580 | 1.5 | 1060 | 598 | 260 | 370 | 732 | 390 | 340 |

| KA42 | 65 | 2 | 8.46 | 14.52 | 5.7~3.3 | 306 | 525 | 3.7 | 1290 | 780 | 275 | 412 | 852 | 410 | 450 |

| KA52 | 80 | 2 | 18.33 | 25.60 | 4.9~3.5 | 358 | 500 | 5.5 | 1510 | 955 | 320 | 472 | 973 | 470 | 540 |

| KA62 | 100 | 2 | 33.68 | 44.32 | 4.8~3.7 | 365 | 475 | 7.5 | 1775 | 1156 | 330 | 502 | 1013 | 500 | 670 |

| KA82 | 125 | 2 | 70.00 | 106.22 | 5.6~3.7 | 313 | 475 | 11 | 2210 | 1483 | 385 | 550 | 1149 | 530 | 890 |

| KA102 | 150 | 2 | 132.92 | 176.64 | 5.8~4.4 | 301 | 400 | 15 | 2660 | 1818 | 445 | 580 | 1239 | 780 | 1110 |

Performance and dimensions of polymer transfer pumps

| Model | Connection (A) |

Dischare pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) | Power (kW) |

Dimensions (appr.) |

Disassembly Space | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | L1 | L2 | H1 | H2 | H3 | W | ||||||

| KA15 | 20 | 2 | 0.18 | 0.67 | 6.4~1.8 | 273 | 960 | 0.4 | 640 | 273 | 245 | 335 | 672 | 310 | 100 |

| KA20 | 32 | 2 | 0.52 | 1.40 | 5.3~2.0 | 328 | 865 | 0.75 | 700 | 315 | 245 | 335 | 672 | 330 | 125 |

| KA30 | 50 | 2 | 1.68 | 5.02 | 6.0~2.0 | 292 | 870 | 1.5 | 910 | 448 | 260 | 370 | 732 | 390 | 190 |

| KA40 | 65 | 2 | 4.23 | 9.61 | 5.7~2.5 | 306 | 695 | 2.2 | 1085 | 580 | 275 | 400 | 790 | 410 | 250 |

| KA50 | 80 | 2 | 7.12 | 14.85 | 6.3~3.0 | 278 | 580 | 3.7 | 1270 | 715 | 320 | 452 | 896 | 470 | 300 |

| KA60 | 100 | 2 | 15.13 | 22.16 | 5.3~3.7 | 328 | 475 | 5.5 | 1475 | 856 | 330 | 502 | 1013 | 500 | 370 |

| KA22 | 32 | 2 | 1.05 | 2.79 | 5.3~2.0 | 328 | 865 | 0.75 | 800 | 415 | 245 | 335 | 672 | 330 | 225 |

| KA32 | 50 | 2 | 3.37 | 10.03 | 6.0~2.0 | 292 | 870 | 1.5 | 1060 | 598 | 260 | 370 | 732 | 390 | 340 |

| KA42 | 65 | 2 | 8.46 | 19.22 | 5.7~2.5 | 306 | 695 | 3.7 | 1290 | 780 | 275 | 412 | 852 | 410 | 450 |

| KA52 | 80 | 2 | 18.33 | 26.69 | 4.9~3.0 | 358 | 580 | 5.5 | 1510 | 955 | 320 | 472 | 973 | 470 | 540 |

| KA62 | 100 | 2 | 33.68 | 44.32 | 4.8~3.7 | 365 | 475 | 7.5 | 1775 | 1156 | 330 | 502 | 1013 | 500 | 670 |

- The above are reference dimensions for equipment layout review.

- When adjusting motor rpm with inverter, use within the range of 20Hz to 60Hz.

- Use an inverter that is one step larger than the motor.

- The motor rpm is based on a 4-pole motor (1750RPM).

- Refer to page 20 for wetted part material and shaft seal specifications.