What’s MONAS?

MONAS is our brand name for the progressive cavity pump series launched by our company.

Progressive cavity pump is a kind of displacement type rotary pump and has outstanding performances for converying high concentration and high-vicosity liquids. This Page is prepared to provide pump users basic informations to understand progressive cavity pumps and MONAS.

- How MONAS works

- Rotational Motion of Rotor

- Mono pump story

How MONAS works

MONAS can transfer high-concentration and high-viscosity liquids as well as water in pulsation free, accurate and uniform flow.

It comes from the outstanding mechanism of metallic rotor and elastomeric stator.

1 Unique shape of Rotor and Stator

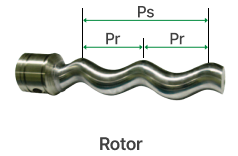

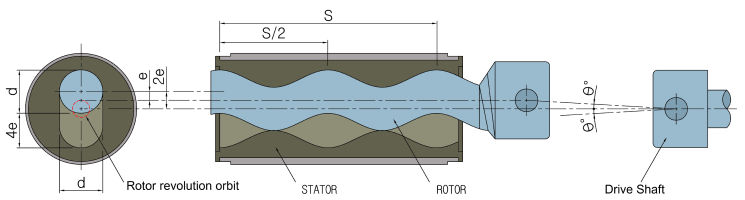

The rotor is a metallic male screw, which has a single external helix with a round cross-section.

The stator is a rubber female screw with an elongated hole of double internal helix.

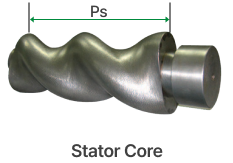

The stator core to mold the stator shows the inside shape of the stator hole.

The pitch Ps of the stator hole is exactly 2 times the pitch Pr of the rotor.

2 Combining and rotating rotor in stator

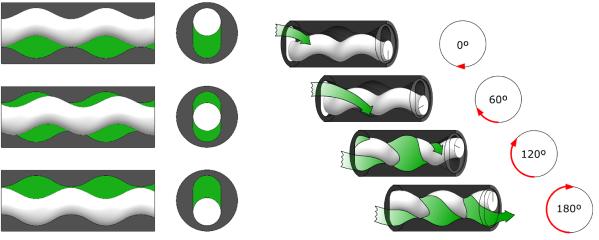

Combining the rotor into the stator hole creates an enclosed space due to the difference in pitch and cross section between them.

When the rotor is rotated inside the stator, rotor is eccentrically rotated in the stator, and the sealed cavity rotates and moves forward, pushing the liquid inside it

3 Continuous rotation of the rotor

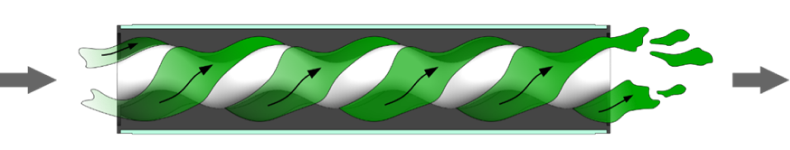

If the rotor is continuously rotated, the rotor rotates in the circumferential direction and pushes the liquid in the cavity as if squeezing it and transfer liquid continuously while rotor does not move forward.

This is called infinite piston motion, because it seems to be the infinite piston continuously moving forward and pushing the liquid away.

Rotational Motion of Rotor

As the rotor has the eccentric axis with an eccentricity ‘e’ from the central axis of the drive shaft,

the rotor performs excentric rotational motion of simultaneously rotating and revolving along an orbit of revolution with a radius of excentricity ‘e’.

1 Discharge Volume

When the rotor rotates one revolution(360°), the cavity between the rotor and the stator progress by one pitch of the stator (2 pitches of the rotor) and the total crosssectional area A of the cavity is uniform in any position.

Therefore, A = 4 x d x e

and the discharge volume V in one revolution is

V = A x S (the pitch of stator)

= 4 x d x e x S

and thus the discharge volume Q for n revolution is

Q = 4 x d x e x S x n

2 Eccentric Motion of Rotor

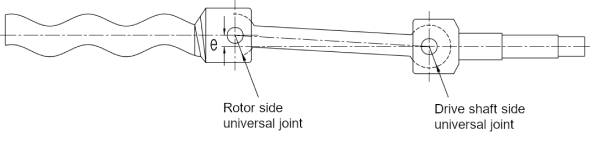

The rotor eccentrically revolves with a constant eccentricity “e”from the centerline of the drive shaft, and the rotational axis of the rotor is parallel to, but does not coincide with, the axis of the drive shaft. Therefore, two universal joints are necessary for the smooth rotation of the rotor.

Mono pump story

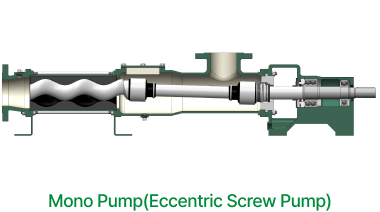

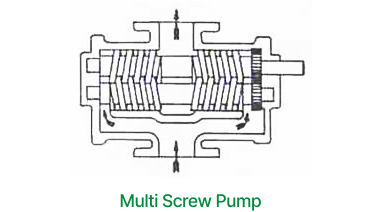

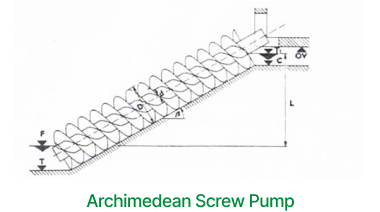

In 1930, a french engineer, Rene Moineau devised a new principle to continuously transfer liquids. He came to invent a new rotary positive displacement pump using this principle. This new pump is often called as Mono Pump after the name of inventor, Rene Moineau, but classifying it by its transferring mechanism, it can be called as an Eccentric Screw Pump, a kind of screw pump among rotary positive displacement pumps. In addition to these, various names such as Progressive Cavity Pump, Helical Rotor Pump, and Eccentric Worm Pump etc. are used for mono pumps. However, please note that Eccentric Screw Pumps(Mono Pumps) are quite different from Multi-axis Screw Pumps, or Archimedean Screw Pumps as below.