Correct Operation

Cautions in operation of MONAS

- 01

-

Do not run the pump when the suction or discharge pipe is blocked

As the MONAS is a positive displacement pump, unlike centrifugal pumps, there is a risk of pump damage, including stator or motor damage, if the pump is operated with a clogged condition. Make sure the suction and discharge pipes are open before starting the pump.

- 02

-

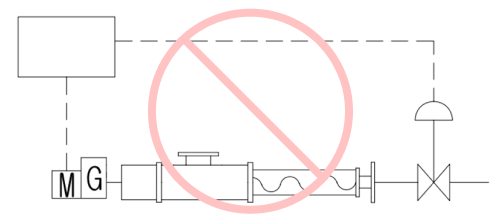

Do not adjust the flow by opening and closing the valve

The flow rate of the mono pump can be easily controlled by adjusting the rotation speed of the pump with an inverter or variater. Unlike the centrifugal pump, It is prohibitted to install a control valve on the discharge side.

- 03

-

Do not dry running

If the pump is running dry without filling the transfer fluid, the stator will be damaged due to the accumulation of frictional heat between the rotor and stator. Be sure to operate the pump filled with liquid, and if there is a high possibility of dry running, a safety device to prevent dry running shall be attached.

What is the dry running?

Dry running occurs in most cases when operating without filling the suction side with liquid during the first operation, after new installation, repair work, cleaning work, etc.

If the rotor and stator are in dry-running with friction without liquid, the temperature of stator rises and the stator cannot emit heat and is damaged. The rate of temperature rise varies greatly depending on the rotational speed of the pump, the material of the stator, and the clearance between the stator and the rotor.

However, if the pump has already been operated and there are no critical defects in the installation conditions such as blockage of the suction pipe, in most cases, some liquid remains inside, so the pump can be restarted without risk of dry running operation. Moreover, the temperature rise to the extent of causing damage does not occur instantaneously, a certain duration of time must elapse, and the unstable operation can be known to some extent in advance due to the tearing noise of the pump during dry running operation. Damage to the stator due to dry running operation can be sufficiently prevented if proper attention to filling the medium is paid.

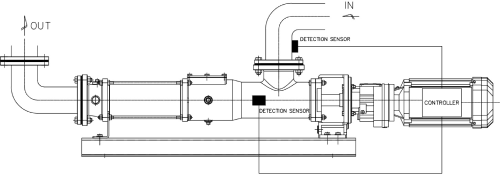

Safety device to prevent dry running operation

The following methods can be considered to prevent dry running. You can select the most suitable method for the application, such as the transfer liquid, installation condition, pump type, and operation method.

- 01

-

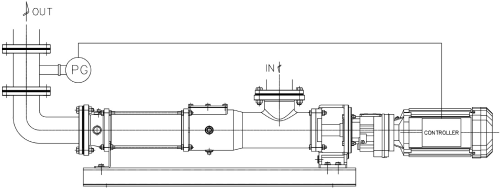

Pressure sensing device

If the liquid on the suction side is not sucked, the discharge pressure will drop, to stop the pump. This method can also be used as an overload protection device when the discharge side is clogged.

- 02

-

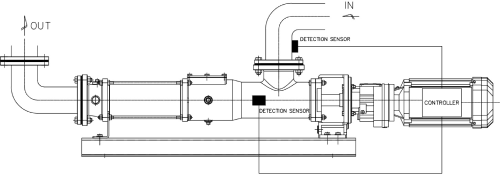

Check the temperature of the stator with a temperature sensor and stop the operation of the pump in case of overheating

- 03

-

Attach the liquid detection device to the suction pipe

Monitoring the liquid inside by electric conduction, inductive, capacitive sound, thermal sensing, sound wave, optical, etc.

- 04

-

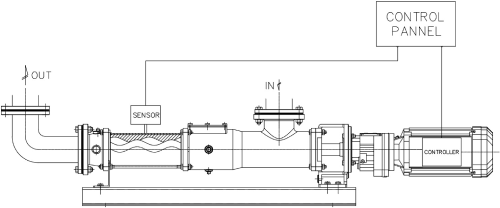

Liquid level monitoring in the suction tank

To monitor the liquid level of the suction tank with a float switch, ultrasonic wave, ball top switch, or mercury switch, and stop the pump when the liquid is empty.