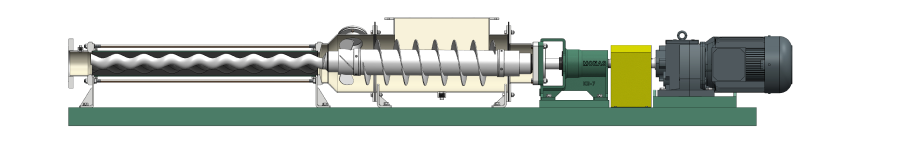

KC For Pressure Feeding of Dehydrated CakePowerful dewatered sludge transfer pump with innovative structure

MONAS-KC Series significantly improves the conveying capability of dehydrated sludge cake

- Large and low wide inlet prevents bridges and improves easy intake of cake

- Large screw enables strong mixing and press-suction of cake

- Multi-stage mono pump display strong discharge performance and the inducer improves suction efficiency

- The divided structure or pump casing and joints allows easy field maintenance (MIP : Maintain In Place)and the rotor / stator can be replaced without dismantling the pump casing (Patent)

- The joint with perfect sealing and protection secure long joint life preventing damages by foreign substance (Patent)

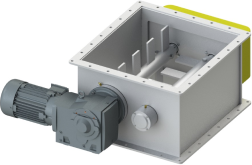

Bearing block type KC-B

Features

- The dehydrated cake is freely transferred through long-distance piping

- The system is simple, convenient to operate, and easy for maintenance

- The closed system is environmentally clean and of no air pollution

- The simple structure with no valve and smooth operation with no pulsation completely solves the shortcomings of the piston pump

Applications

- Dehydrated cake, high-viscosity pulp, ceramic soil, clay, silt, fruit juice residue, fish meat, etc

Bearing block KC-B in-line Type

Bearing block type that can be used with various reduction motors A compact monoblock type is also available as the driver and pump are directly coupled

- KR Relay pump

- Performance and dimensions Standard

- Performance and dimensions with Paddle Mixer

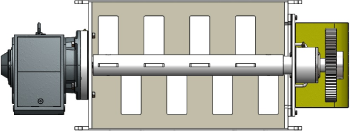

- Paddle Mixer

KR type Relay pump for long-distance transfer of dewatered cake

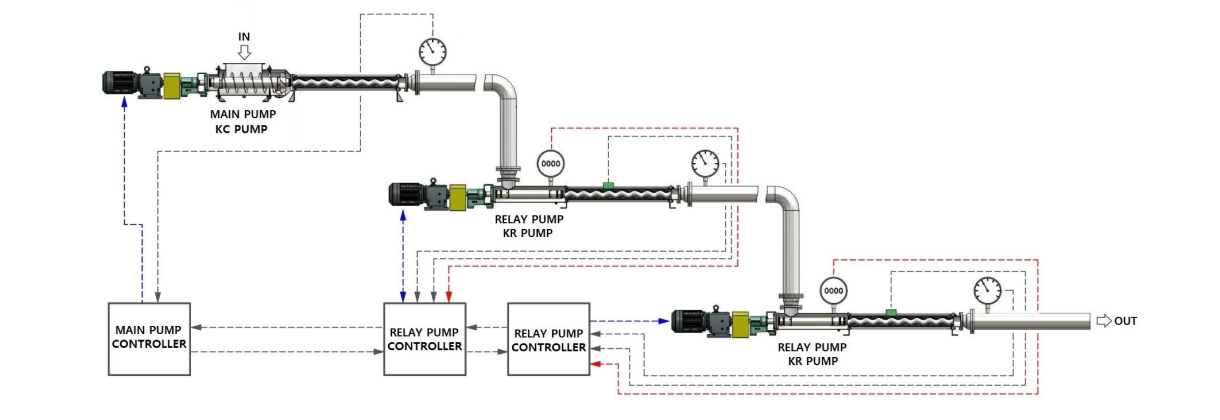

Long distance transfer is possible by connecting KC type (main feeding pump) and KR type (relay pump) in series. If long-distance transfer is required, please contact us.

Long-distance transfer of sludge by relay pump

Bearing block type KR-B

Diagram of relay transfer using KR relay pump

If long-distance transfer is required, please contact us.

Performance and dimensions

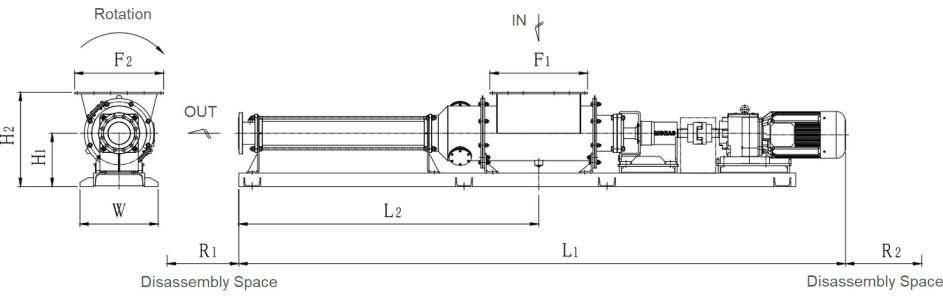

Performance and dimensions of KC type

| Model | Connection (A) |

Discharge Pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) |

Power (kW) |

Dimensions (appr.) |

Wt (kg) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | L1 | L2 | H1 | H2 | F1 | F2 | R1 | R2 | W | |||||||

| 2KC40 | 100 | 8 | 1.81 | 17.25 | 105 | 3.7 | 2813 | 1196 | 330 | 580 | 625 | 560 | 450 | 350 | 580 | 422 |

| 4KC40 | 100 | 16 | 1.81 | 16.66 | 105 | 5.5 | 3265 | 1596 | 330 | 580 | 625 | 560 | 850 | 350 | 580 | 492 |

| 2KC50 | 125 | 8 | 2.81 | 17.25 | 105 | 5.5 | 2880 | 1319 | 340 | 590 | 625 | 560 | 540 | 350 | 580 | 556 |

| 4KC50 | 125 | 16 | 2.81 | 16.96 | 105 | 7.5 | 3630 | 1799 | 340 | 590 | 625 | 560 | 1020 | 350 | 580 | 654 |

| 2KC60 | 125 | 8 | 5.23 | 16.96 | 105 | 7.5 | 3271 | 1440 | 340 | 590 | 625 | 560 | 670 | 500 | 580 | 631 |

| 4KC60 | 125 | 16 | 5.23 | 16.96 | 105 | 11 | 3955 | 2040 | 340 | 590 | 625 | 560 | 1270 | 500 | 580 | 740 |

| 2KC80 | 150 | 8 | 10.84 | 16.96 | 105 | 11 | 3857 | 1793 | 395 | 700 | 724 | 660 | 890 | 500 | 580 | 919 |

| 4KC80 | 150 | 16 | 10.84 | 17.65 | 105 | 22 | 4870 | 2593 | 395 | 700 | 724 | 660 | 1690 | 500 | 580 | 1157 |

| 2KC100 | 200 | 8 | 18.9 | 17.65 | 105 | 22 | 4730 | 2234 | 525 | 905 | 824 | 760 | 1110 | 850 | 930 | 1527 |

| 4KC100 | 200 | 16 | 18.9 | 16.56 | 105 | 37 | 6029 | 3234 | 525 | 905 | 824 | 760 | 2110 | 850 | 930 | 2012 |

| 2KC120 | 250 | 8 | 32.66 | 16.86 | 105 | 30 | 5213 | 2513 | 525 | 905 | 824 | 760 | 1330 | 850 | 930 | 1890 |

| 4KC120 | 250 | 16 | 32.66 | 16.47 | 105 | 45 | 6508 | 3713 | 525 | 905 | 824 | 760 | 1330 | 850 | 930 | 2463 |

Performance and dimensions

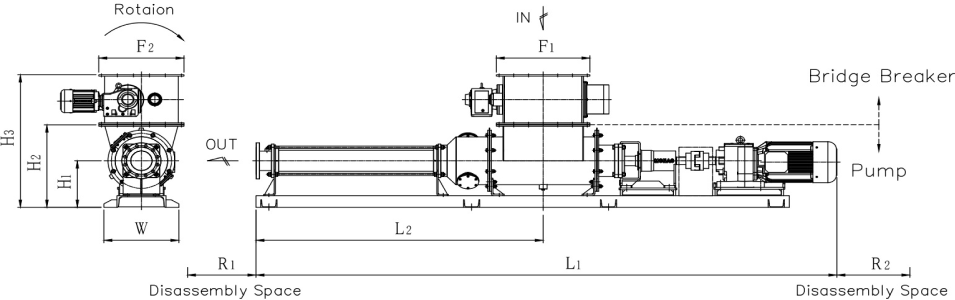

Performance and dimensions of KC type – with Paddle mixer

In general, the KC Pump can transfer sludge without a paddle mixer, and in particular, a paddle mixer is rather unnecessary in case of forced input by a screw conveyor or natural intake by positive suction head beneath the storage tank.

| Model | Paddle Mixer |

Connection (A) |

Discharge Pressure (kgf/cm²) |

Flow rate (m³/hr) |

Reduction ratio | Rotation (rpm) |

Power (kW) |

Dimensions (appr.) | Wt (kg) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | Mixer | L1 | L2 | H1 | H2 | H3 | F1 | F2 | R1 | R2 | W | ||||||||

| 2KC40 | W11 | 100 | 8 | 1.81 | 17.25 | 105 | 3.7 | 1.5 | 2813 | 1196 | 330 | 580 | 950 | 625 | 560 | 450 | 350 | 580 | 585 |

| 4KC40 | W11 | 100 | 16 | 1.81 | 16.66 | 105 | 5.5 | 1.5 | 3265 | 1596 | 330 | 580 | 950 | 625 | 560 | 850 | 350 | 580 | 655 |

| 2KC50 | W11 | 125 | 8 | 2.81 | 17.25 | 105 | 5.5 | 1.5 | 2880 | 1319 | 340 | 590 | 960 | 625 | 560 | 540 | 350 | 580 | 719 |

| 4KC50 | W11 | 125 | 16 | 2.81 | 16.96 | 105 | 7.5 | 1.5 | 3630 | 1799 | 340 | 590 | 960 | 625 | 560 | 1020 | 350 | 580 | 817 |

| 2KC60 | W11 | 125 | 8 | 5.23 | 16.96 | 105 | 7.5 | 1.5 | 3271 | 1440 | 340 | 590 | 960 | 625 | 560 | 670 | 500 | 580 | 794 |

| 4KC60 | W11 | 125 | 16 | 5.23 | 16.96 | 105 | 11 | 1.5 | 3955 | 2040 | 340 | 590 | 960 | 625 | 560 | 1270 | 500 | 580 | 903 |

| 2KC80 | W12 | 150 | 8 | 10.84 | 16.96 | 105 | 11 | 2.2 | 3857 | 1793 | 395 | 700 | 1125 | 724 | 660 | 890 | 500 | 580 | 1162 |

| 4KC80 | W12 | 150 | 16 | 10.84 | 17.65 | 105 | 22 | 2.2 | 4870 | 2593 | 395 | 700 | 1125 | 724 | 660 | 1690 | 500 | 580 | 1400 |

| 2KC100 | W13 | 200 | 8 | 18.9 | 17.65 | 105 | 22 | 3.7 | 4730 | 2234 | 525 | 905 | 1380 | 824 | 760 | 1110 | 850 | 930 | 1869 |

| 4KC100 | W13 | 200 | 16 | 18.9 | 16.56 | 105 | 37 | 3.7 | 6029 | 3234 | 525 | 905 | 1380 | 824 | 760 | 2110 | 850 | 930 | 2354 |

| 2KC120 | W13 | 250 | 8 | 32.66 | 16.86 | 105 | 30 | 3.7 | 5213 | 2513 | 525 | 905 | 1380 | 824 | 760 | 1330 | 850 | 930 | 2232 |

| 4KC120 | W13 | 250 | 16 | 32.66 | 16.47 | 105 | 45 | 3.7 | 6508 | 3713 | 525 | 905 | 1380 | 824 | 760 | 1330 | 850 | 930 | 2805 |

Paddle Mixer

When transferring the dehydrated cake directly falling from the dehydrator with the KC type pump, if the cake has very low moisture content, and the upper intake hopper has a structure where the cake is easily stagnant, the intake of cake may not be sufficient and the performance of the pump becomes degraded.

In this case, a paddle mixer may be installed above the pump inlet to stir and degas the dehydrated cake as pretreatment, thereby minimizing air intake and improving pump performance.

However, in general, the KC Pump can transfer sludge without a paddle mixer, and in particular, a paddle mixer is rather unnecessary in case of forced input by a screw conveyor or natural intake by positive suction head beneath the storage tank.